Are you fully utilizing the potential of the sweater manufacturing process for your fashion line? Understanding this complex journey is key to elevating your knitwear offerings.

Our expertise in the clothing sector positions us to guide you through the complexities of sweater production. We provide insights that are applicable to you, enhancing both efficiency and product quality.

Navigating the sweater manufacturing process effectively can elevate your brand and products above the competition. This involves a detailed understanding of each step, ensuring every sweater meets the highest standards of quality.

In this guide, you’ll gain comprehensive knowledge of the vital steps involved in sweater manufacturing, equipping you with tools to optimize your production line and develop garments that stand out.

So here we go!

Step#1 Design and Pattern Making

Design and pattern making is a foundational stage where creativity meets precision, setting the tone for the entire sweater manufacturing process. Here are the key actions required:

- Trend Analysis: The process begins with a thorough investigation of current fashion trends and foresight into future styles. A mood board, featuring images, colors, and textures aligned with the design vision, is assembled to guide the design journey.

- Sketching and Illustration: The design concept is then brought to life through detailed sketching and illustration. Various design elements are explored, providing a visual representation that serves as the foundation for pattern making. Examples of these are silhouettes, necklines, and sleeve styles.

- Fabric and Trim Selection: After finalizing the design sketches, appropriate fabrics and trims are selected. Sweater’s intended use, seasonality, and desired texture are considered while choosing. This is vital to ensure that final product aligns with the design vision and meets market expectations.

- Technical Specification Sheet Creation: Technical specification sheet for the design is developed. This document includes the measurements, construction notes, and finishing details, serving as a comprehensive guide for the pattern maker and production team.

Step#2 Yarn Selection

Transitioning from the initial design and pattern-making, yarn selection is vital in determining the texture, appearance, and overall quality of the sweater. Here are the aspects to consider during this stage:

- Fiber Type: Desired characteristics of the sweater, such as warmth, softness, or durability, are identified. In line with this, the fiber type like wool, cotton, synthetic, or a blend that best matches these requirements is selected.

- Color Choice: Design concept and seasonality is reviewed to decide on the yarn colors. Picking the perfect color that will bring the design to life is always exciting. Color swatches are utilized to accurately match the palette and ensure consistency across production batches.

- Yarn Weight: The yarn weight is determined ensuring it complements with the design’s texture and drape. Yarn weight charts are used for consultation to make sure it is matched to the specific requirements of the pattern for the desired outcome.

- Sustainability: If sustainability is a priority, yarns made from eco-friendly materials or processes are chosen with certifications that guarantee the sustainability claims of the yarn suppliers.

Step#3 Yarn Preparation

Afte the careful selection of yarn, its preparation is essential for ensuring it is ready for the knitting phase. Here are the fundamental tasks that need to be undertaken to prepare the yarn for manufacturing:

- Winding: The yarn is wound onto cones to facilitate ease of use during the knitting process. This ensures that the yarn feeds smoothly into the knitting machines, preventing snags and ensuring consistency in the knitting tension.

- Twisting: To enhance the yarn’s strength and texture, twisting is performed. This involves combining two or more strands of yarn, which not only contributes to the durability of the finished sweater but also can introduce interesting textural elements.

- Dyeing: If the yarn hasn’t been dyed previously, it is now colored to match the design specifications. The dyeing process is carefully managed to achieve uniform color saturation and to ensure that the yarn’s quality is not compromised.

- Quality Check: The yarn undergoes a detailed examination where it is checked for uniformity, color consistency, and any signs of defects. This is crucial to prevent any issues from arising during the knitting phase, ensuring the final product meets the desired standards.

Step#4 Knitting

Moving beyond the yarn preparation, the knitting phase transforms the prepared yarns into the various components of a sweater. Here are the detailed processes within this critical phase:

- Knitting Machine Setup: Knitting machines are set up according to the specific design needs. Settings are adjusted to match the pattern and yarn type. These machines are vital in this process, given the expected 4.0% CAGR market growth from 2022 to 2030, as per Research and Markets.

- Panel Knitting: Individual parts of the sweater, such as the front, back, and sleeves are knitted following the design pattern closely, paying attention to size and shape ensuring they fit together smoothly in later stages.

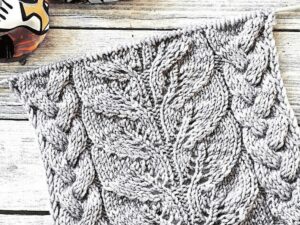

- Pattern Integration: As each panel is being knitted, design elements specified in the pattern are integrated, such as cable knits or color blocks. This requires adjusting the knitting machine or manually changing yarns to create the desired patterns and textures.

- Dimension Control: Throughout the knitting process, continuous measuring of the dimensions of each knitted piece against the pattern’s specifications is performed. This ensures that each part of the sweater will fit as designed, preventing any issues during assembly.

- Detailing: After the main parts are knitted, any detailed work such as ribbing at the cuffs and hem or neckline finishes are added. This often requires switching to different knitting techniques or attachments to achieve the precise look and feel dictated by the design.

Step#5 Assembling and Linking

After the meticulous process of knitting, the next stage is assembling and linking, transforming separated knitted panels into a complete garment. Here are the essential tasks to be carried out during this phase:

- Piece Layout: The knitted sections are arranged on a flat surface according to the assembly plan. This organization helps ensure each piece is in its correct position for smooth assembly.

- Seaming: A specialized linking machine is utilized to join the pieces together. It’s like giving the sweater a perfect hug, bringing all the pieces into one. Edges and seams are carefully aligned for a neat finish, ensuring the sweater’s shape is accurately maintained.

- Neckline Finishing: The neckline or collar is then attached to the main body. This requires careful stitching to ensure the neckline fits well and adds to the sweater’s aesthetic appeal. Hongyu Apparel integrates great precision in this process, enhancing the overall quality and appeal of the garment.

- Sleeve Setting: The sleeves are attached to the armholes of the sweater’s body. Proper alignment is essential here to ensure that the sleeves allow for comfortable movement and a perfect fit.

- Final Assembly Check: After all pieces have been assembled, a thorough check of the garment is conducted to ensure that everything is correctly put together and the sweater meets the design specifications.

Step#6 Finishing Touches

Following the meticulous assembly of sweater components, finishing touches is vital for enhancing the garment’s aesthetic and ensuring its market readiness. Here are the key actions to take at this stage:

- Washing: The sweater is thoroughly cleaned to remove any leftover debris or chemicals from the manufacturing process. The garment is soaked and gently agitated in a water and detergent mixture, then rinsed clean to ensure it’s free of any residues.

- Blocking: The sweater is dampened and laid out on a flat surface. It’s then shaped to match the pattern’s dimensions, using pins if necessary, to dry in the correct form, ensuring the final product has the intended shape and size.

- Trimming: Careful examination on the sweater for any loose threads or imperfections that might have been overlooked in earlier stages is performed. Scissors or a trimming tool are used to meticulously cut away, refining the sweater’s appearance.

- Adding Embellishments: If needed, various decorative techniques are included. For instance, buttons are sewn on securely, beads are attached where the design specifies, or embroidery is added, enhancing the sweater’s visual appeal with these detailed touches.

- Pressing: To ensure the sweater looks its best, pressing is done. It’s amazing how this stage brings out the sweater’s true beauty. A low-heat iron is gently passed over the fabric, smoothing out any wrinkles or creases, which results in a polished, ready-to-wear finish.

Step#7 Quality Control and Inspection

Once finishing touches have been applied, the next phase is quality control and inspection to ensure every product meets the industry’s highest standards. Here are key tests implemented:

- Dimensional Check: Each sweater is measured against its design specifications to ensure it matches the intended size. A ruler or measuring tape is used to check the dimensions of various sweater parts, like the length, width, and sleeve length, ensuring they align with the pattern’s measurements.

- Visual Inspection: This involves a thorough examination of the sweater for any visual flaws, such as misaligned patterns, loose threads, or color variations. Each garment is meticulously checked, turning it inside out if necessary, to identify any defects that could compromise the sweater’s appearance.

- Performance Testing: Sweaters are tested for their ability to withstand wear and washing. This might involve subjecting the garment to repeated wash cycles or wear simulations to assess its durability, fabric resilience, and colorfastness, ensuring the product will maintain its quality over time.

- Final Approval: If a sweater passes all the tests, it receives final approval, confirming its readiness for the next stage in the process. Seeing a garment makes it through approval feels rewarding. While those that did not pass are either sent back for adjustments or marked for rejection.

Step#8 Packaging and Distribution

Upon ensuring each sweater passes the strict criteria, the focus shifts towards preparing the product for its final journey to the customer in packaging and distribution. Here are the steps involved:

- Labeling: Labels detailing care instructions and brand identity are attached to each sweater. This involves physically affixing the labels to the garment. Hongyu Apparel’s expertise ensures that this step showcases your brand’s commitment to quality and consumer information.

Below is a table that summarizes the key aspects of labeling sweaters with care instructions and brand identity.

| Step | Description | Importance | Technique | Outcome |

| 1. Design | Creating a label that includes brand logo, care instructions, and material composition. | Establishes brand identity and informs consumers. | Graphic design software is used to layout and design the labels. | A label that is visually appealing and informative. |

| 2. Material Selection | Choosing the right material for the label that will last the lifecycle of the garment. | Ensures durability and comfort. | Materials like polyester, cotton, or satin are selected based on the garment fabric. | A durable label that matches the garment’s quality and feel. |

| 3. Printing | Transferring the label design onto the chosen material. | Provides clarity and legibility of the information. | Techniques include screen printing, thermal transfer, or digital printing. | High-quality labels with clear, fade-resistant text and graphics. |

| 4. Attachment | Physically affixing the label to the sweater. | Secures the label in a position that is easily visible and accessible. | Sewn in with a sewing machine, ensuring it’s firmly attached without damaging the garment. | A label that is securely attached and positioned for easy visibility. |

| 5. Quality Check | Inspecting the labeled garment for any defects. | Guarantees the label meets the brand’s quality standards. | Manual inspection to ensure the label is correctly attached and the information is accurate. | A final product that represents the brand’s commitment to quality and consumer satisfaction. |

- Folding and Packaging: Sweaters are folded to maintain their form and then placed into packaging designed for transport. The folding is done methodically, and the sweater is then secured in packaging material.

- Inventory Management: Packaged sweaters are recorded in the inventory system. This involves entering product details into the database to track the location and quantity of stock.

- Shipping: Finally, the sweaters are sent out to their destination. It’s a journey we meticulously plan for each piece. This involves selecting dependable couriers and shipping methods to guarantee the quick and safe arrival of the products.

Dive Deeper Into Our Resources

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Conclusion

Understanding the essential steps of sweater manufacturing reveals the meticulous craftsmanship behind every piece. This guide serves as a crucial resource, equipping businesses with the knowledge to enhance their fashion line through this manufacturing process.

If you’re looking to elevate your sweater collection, partner with Hongyu Apparel, a leading manufacturer known for premium sweater production. Contact us to explore how we can bring your designs to life.

By Kiki

By Kiki